Creating a culture focused on safety requires commitment from all levels of an organization. The foundation of safety culture development is consistently measuring and managing your facility’s safety performance using leading and lagging indicators. Additionally, implementing behavior-based safety training is crucial in achieving a safe work environment at your facility.

What are leading indicators?

A leading indicator is a proactive, preventive measure used to drive and assess activities carried out to avoid and control injuries. Examples include:

- Safety training and key performance indicators (KPIs)

- Ergonomic opportunities

- Safety audits

- Safety site plans

These indicators are proactive and focus on future safety performance and continuous improvement. They report what employees are regularly doing to prevent injuries.

What are lagging indicators?

Lagging indicators measure the occurrence and frequency of a company’s incidents in the form of past accident statistics. Examples include:

- Injury frequency and severity

- OSHA recordable injuries

- Workers’ compensation costs

- Lost time incident rates

These traditional safety metrics gauge progress toward compliance with safety rules. The metrics detail the number of injuries, severity, and overall effectiveness of the safety measures within your warehouse.

Why use leading and lagging indicators?

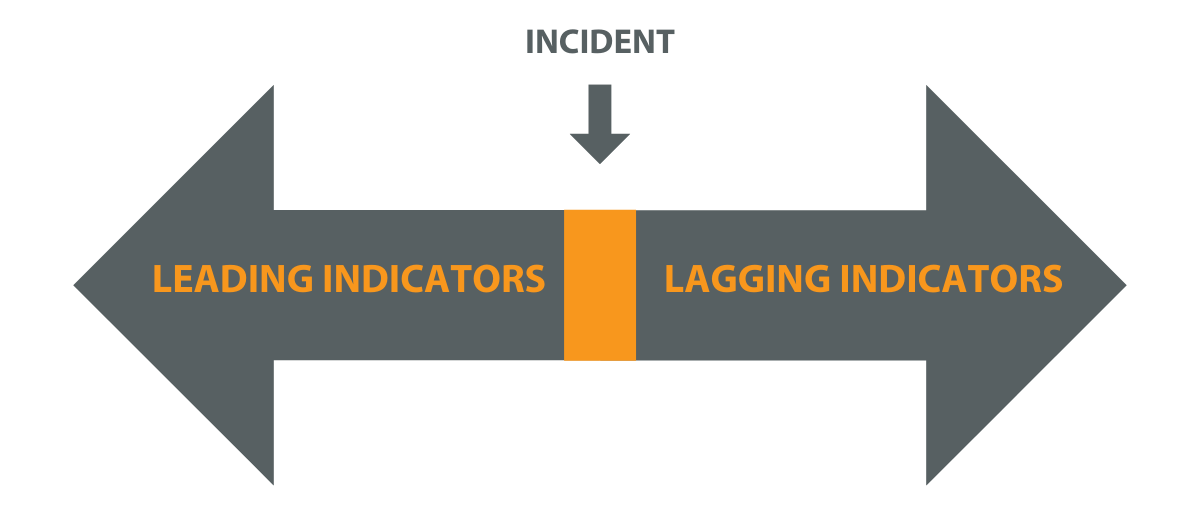

Combining leading and lagging indicators provides a well-rounded approach for warehouse safety management and can highlight ways to improve warehouse safety. While lagging indicators can reveal the existence of hazards or areas of failure, leading indicators can attest to how effectively your safety programs prevent incidents. Here is a simple visual of how leading and lagging indicators work

together:

The Importance of Accountability

Taking responsibility for your safety as well as the safety of your colleagues and employees proactively reduces hazards and incidents. However, creating a safety-focused culture starts with accountability from leadership. A company’s safety culture is a direct reflection of management’s commitment. Leaders must ensure employees have the resources they need to succeed and clearly communicate expectations while setting an example.

WOW Logistics’ Effective Safety-focused Culture

WOW Logistics is dedicated to a systematic safety approach that requires commitment from top leadership to frontline employees. We believe safety is everyone’s responsibility. Our safety promise states:

- Nothing is worth getting hurt over

- Every accident/injury is preventable

- Everyone is responsible for looking out for his/her fellow employee

- Every individual is responsible for his/her safe behavior

- WOW Logistics is committed to safety as the number one priority

- All incidents will be reported to a supervisor immediately

This safety promise and our safety vision are posted at each location for everyone to see, reiterating their importance. Each distribution center must have its safety site plan, supervisor scorecards, and safety KPI reports reviewed monthly by the Environment, Health, and Safety Manager.

WOW’s onboarding programs teach appropriate safety practices from the onset with training plans for each piece of material handling equipment (MHE). Our behavior-based training addresses unsafe actions at their core and helps create a culture focused on safety. When an incident does occur, it must be reported within an hour and investigated within 24 hours.

This safety-focused culture and expertise is at the core of our business and is evident in our superior supply chain solutions, including Contract Operations, Transportation Services, and Real Estate Solutions.

Learn more about WOW Logistics by exploring our website.